What Is Low-Volume Manufacturing?

Low-volume manufacturing is a specialized service that offers full production-quality parts but in volumes ranging from a single piece to a few thousand pieces. It’s ideal for moving an idea from the concept stage through prototyping, and from there as a bridge to full volume production.

Low volume production is considered to be a specialized service because most manufacturers don’t want to do it. Their assembly lines and supply chains are optimized for large production volumes that leverage economies of scale. There is nothing wrong with that approach, because it’s the best way to ensure the lowest cost per piece. However, it usually requires large minimum order volumes and a commitment to expensive tooling.

But what is a product developer to do if you want to start off with product volumes on the low end, from one part to one thousand? That’s where 3D-Tiger can help.

How To Process Low-Volume Manufacturing?

What is the secret to low volume manufacturing success? Is there a difference in the types of raw materials that are used, the way that they’re processed, or the quality of the finished product?

Our clients are concerned that low-volume manufacturing doesn’t mean compromising quality or precision when compared to full production manufacturing. Rest assured that when we process lower volume orders we use the same materials, the same equipment, and the same rigorous quality control.

How do we do it? We’re experts in high-mix, low volume production because our systems are optimized to be scalable, from one part to a million. That means we have a robust supply chain of raw materials so you won’t be burdened with minimum order volume restrictions. And we have a digital manufacturing platform that ties all of our equipment together into a single network. That allows us to allocate resources quickly and efficiently between work centers in order to process even complex orders fast.

What makes low-volume production service unique?

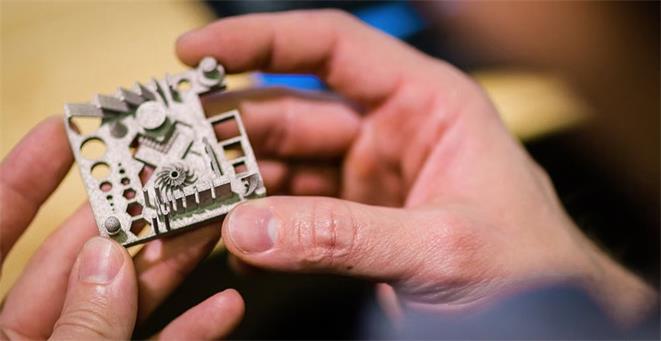

There are several factors that separate our low-volume production service from the competition. For one, we offer an extensive variety of complementary in-house services — including CNC machining, vacuum casting, plastic injection molding, and finishing — to deliver our clients comprehensive prototyping and NPI (new product introduction) solutions.

Secondly, we offer best-in-class material verification and testing services. Plus, we don’t require a minimum order volume or minimum dollar value, and we will provide fast, accurate quotes.

Does 3D-Tiger manufacture the products?

Yes, our team completes all manufacturing at our facilities. This gives us a quality control advantage over other low-volume production services that outsource their manufacturing.

What materials does 3D-Tiger work?

We routinely work with all conventional metals including copper, brass, stainless and mild steel, magnesium, and aluminum. We also have a robust supply chain with thousands of commercial plastic resins, including transparent plastics, engineering- and medical-grade plastics, glass-filled plastics, and more.

Get Your Project Started Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.