Shaping the Future in Metal Layers

Crafting Excellence in Every Layer of Metal

Additive Minds, Constructive Designs.

At 3D-Tiger, Our Focus Is On Providing You With The Finest Services In 3D Printing, CNC Machining, Rapid Prototyping, And Low-Volume Manufacturing.

ConsultationShenzhen 3D-Tiger Metal Printing Com.LTD.

TianHui Building,Gongming,Shenzhen,Guangdong,China

Since 2020, 3D-Tiger has been a leading provider of solutions, offering exceptional services in 3D metal printing, CNC machining, Gear production, and low-volume manufacturing across diverse applications. Our dedicated team of engineers and technicians specializes in producing custom parts using cutting-edge equipment and techniques, including multi-axis CNC machining and advanced 3D metal printing processes. Our expertise extends beyond common materials to include the printing of rare materials like base alloys, refractory high entropy alloys, spherical tantalum powder, tantalum tungsten alloy powder, niobium powder, and niobium tungsten alloy powder processing. Combined with original CNC machining, we achieve complex structures and high precision simultaneously.

Additive manufacturing make the workpieces flexibly and efficiently. Focus on the parts with highly complex and robust, without compromising on being light weight. Realize urgently need spare parts, no time pressure.

Highly accurate and precise multi-axis CNC milling and turning of mild and stainless steel, aluminum, brass, and hardened steels for your most demanding applications.

Offering the helical gear, straight gear, inner gear, outer gear, round wheel, ring gear, sun gear and planetary gear. Including industrial grade synchronous gears, transmission gears for electric vehicles, and planetary gears for motors.

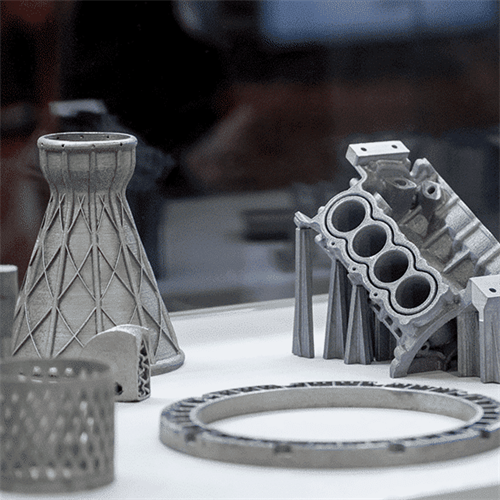

In additive manufacturing, also known as generative manufacturing, workpieces are produced layer upon layer through laser sintering, whereby metal powder is melted layer by layer using a laser beam. In contrast to subtractive manufacturing, i.e. CNC machining, additive machining enables highly complex components to be manufactured in one piece. This makes it feasible to create shapes which would otherwise be all but impossible to manufacture. SLM processing also offers a high degree of flexibility when producing, which is particularly important when dealing with spare parts and prototypes.

The production of components has been revolutionised with 3D printing: Prototypes and spare parts can be produced faster and more cost-effectively. Moving forward, the benefits of additive manufacturing, such as weight reduction and rapid manufacturing, will also facilitate the production of standardised parts. Combining 3D printing technology and multiple axis CNC machining prompt the parts not only realize complex structures, but also high-precision requirements.

Offering a range of services that allow for rapid product introduction, quick response times to changing market conditions and a robust supply chain offering many types of material for every application.

3D-Tiger brings unparalleled expertise in rapid prototyping, 3D metal printing, and low-volume manufacturing, utilizing the latest technologies including multi-axis CNC machining and gear production.

Talk to us about your next project

Copyright © 2023.3D-Tiger All rights reserved.